Thermoforming cups are ubiquitous in our daily lives, from grabbing a coffee on the go to enjoying a refreshing soda at a party. This seemingly simple yet ingenious invention has revolutionized the beverage industry, offering numerous advantages over traditional cups. In this comprehensive guide, we will delve into the world of thermoforming cups, exploring their history, manufacturing process, benefits, and applications.

What are Thermoforming Cups?

Thermoforming cups are a type of disposable cup made from plastic or paper using a process called thermoforming. This process involves heating a sheet of plastic or paper to a pliable state and then using a vacuum or pressure to form it into the desired shape. Thermoforming cups are incredibly versatile and can be customized to meet specific needs, making them ideal for a wide range of applications.

The History of Thermoforming Cups

The origins of thermoforming can be traced back to the early 20th century when the first thermoforming machines were developed. However, it wasn’t until the 1950s that thermoforming cups gained widespread popularity. This surge in popularity was driven by several factors, including the increasing demand for disposable cups, the development of new and improved plastics, and the affordability of thermoforming technology.

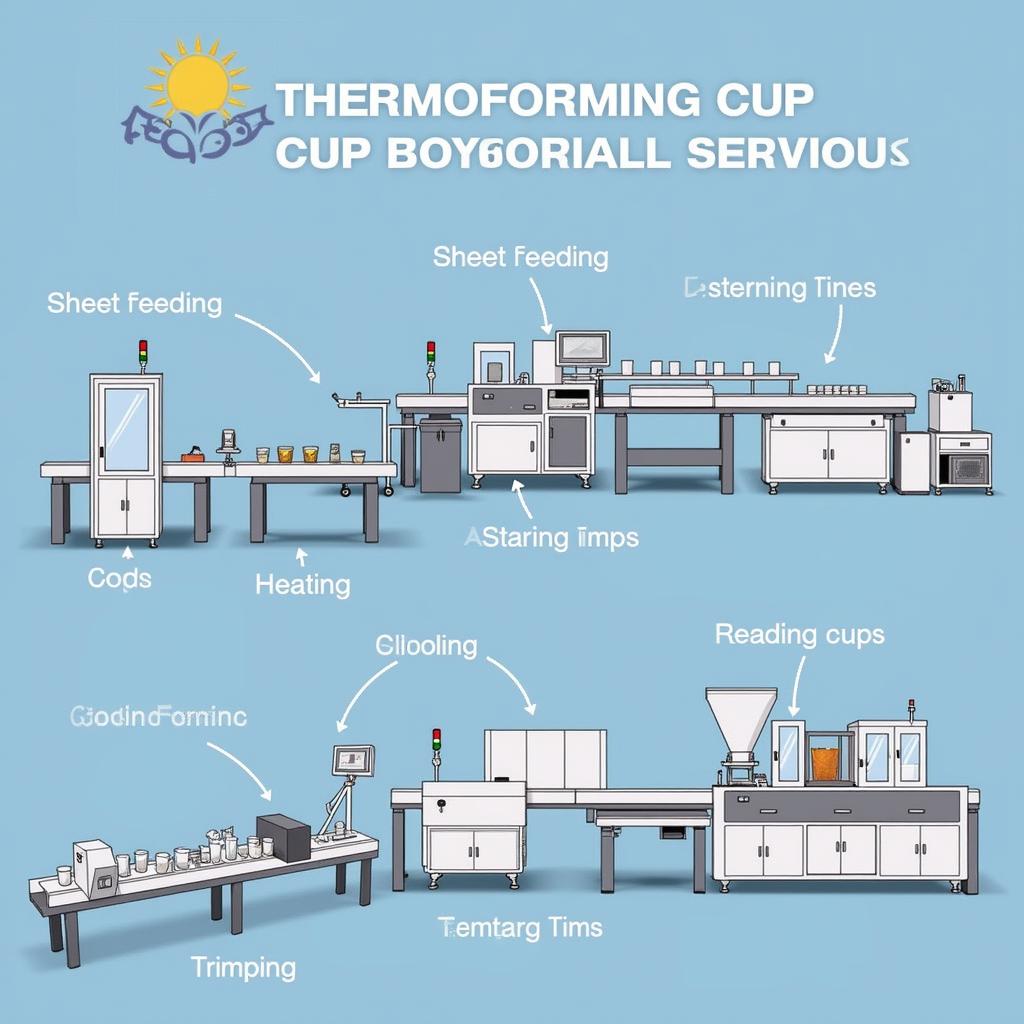

The Thermoforming Process

The thermoforming process involves several key steps:

- Sheet Preparation: A sheet of plastic or paper is fed into the thermoforming machine.

- Heating: The sheet is heated to a specific temperature, causing it to soften and become pliable.

- Forming: The heated sheet is then drawn into the mold using a vacuum or pressure.

- Cooling: The formed cup is cooled and solidified.

- Trimming: Excess material is trimmed to create the desired shape and size.

Advantages of Thermoforming Cups

Thermoforming cups offer a wide range of advantages over traditional cups, including:

- Durability: Thermoforming cups are highly resistant to breakage and can withstand rough handling.

- Versatility: They can be customized in terms of size, shape, and design to meet specific needs.

- Affordability: Thermoforming cups are generally less expensive to produce than traditional cups.

- Lightweight: They are lightweight and easy to handle, making them ideal for on-the-go use.

- Leak-proof: Thermoforming cups are designed to be leak-proof, preventing spills and messes.

- Hygienic: The smooth surface of thermoforming cups makes them easy to clean and sanitize.

- Recyclable: Many thermoforming cups are made from recyclable materials, promoting sustainability.

Applications of Thermoforming Cups

Thermoforming cups find wide applications in various industries, including:

- Food and Beverage: These cups are widely used for serving hot and cold beverages, ice cream, yogurt, and other food products.

- Healthcare: Thermoforming cups are used for dispensing medication, storing samples, and other medical applications.

- Industrial: They are used in industrial settings for packaging and storage of various materials.

- Retail: Thermoforming cups are used for packaging products such as cosmetics, toiletries, and other consumer goods.

The Future of Thermoforming Cups

As technology continues to advance, we can expect to see even more innovative and sustainable thermoforming cups in the future. The focus will be on developing cups made from recycled materials, biodegradable plastics, and sustainable paper alternatives.

Frequently Asked Questions (FAQ)

Q: What is the difference between thermoforming and injection molding?

A: Thermoforming and injection molding are both methods of plastic processing, but they differ in how the plastic is heated and molded. Thermoforming uses a sheet of plastic that is heated and then drawn into a mold, while injection molding involves injecting molten plastic into a mold.

Q: Are thermoforming cups safe for use with hot beverages?

A: Many thermoforming cups are made from materials that are safe for use with hot beverages. However, it is important to check the packaging or manufacturer’s instructions to ensure that the cup is suitable for the intended use.

Q: Are thermoforming cups recyclable?

A: The recyclability of thermoforming cups depends on the material they are made from. Some cups are made from recyclable plastics, while others are made from non-recyclable materials. It is important to check the recycling guidelines in your area to determine if thermoforming cups can be recycled.

Q: What are the environmental implications of using thermoforming cups?

A: The environmental impact of thermoforming cups depends on the materials used and the manufacturing process. While thermoforming cups can be recyclable, many end up in landfills, contributing to waste accumulation. The use of recycled materials and biodegradable plastics can help reduce the environmental impact of thermoforming cups.

Conclusion

Thermoforming cups have played a vital role in revolutionizing the beverage industry and our daily lives. Their durability, versatility, and affordability make them ideal for a wide range of applications. As technology continues to advance, we can expect to see even more innovative and sustainable thermoforming cups in the future.

If you have any further questions, please feel free to contact us at:

Số Điện Thoại: 0372999996, Email: bong.da@gmail.com

Hoặc đến địa chỉ: 236 Cầu Giấy, Hà Nội.

We have a dedicated customer service team available 24/7 to assist you.