Ink Cup Pad Printing is a versatile printing technique widely used for various applications. It offers a cost-effective solution for transferring images and designs onto a wide range of materials, including plastics, metals, ceramics, and glass. This article delves into the intricacies of this printing method, exploring its benefits, applications, and key considerations.

Understanding Ink Cup Pad Printing

Ink cup pad printing, also known as pad printing, is a specialized printing process that involves transferring ink from an engraved printing plate onto a flexible pad. This pad then transfers the inked image onto the desired substrate. The process is highly versatile and adaptable, allowing for precise and detailed printing on curved and irregular surfaces.

Key Components of Ink Cup Pad Printing

The process involves several key components:

- Ink Cup: Holds the ink and is typically made of metal or plastic.

- Printing Plate: A metal or photopolymer plate with an engraved design or image.

- Pad: A flexible, silicone pad that picks up ink from the plate and transfers it to the substrate.

- Substrate: The surface onto which the image is printed, such as plastic, metal, glass, or ceramics.

How it Works

The ink cup pad printing process follows a series of steps:

- Ink Application: Ink is poured into the ink cup, ensuring it’s evenly distributed.

- Plate Engagement: The printing plate is brought into contact with the ink surface, allowing the ink to fill the engraved design.

- Pad Transfer: The pad is pressed onto the inked plate, picking up the design.

- Substrate Impression: The pad is then pressed onto the substrate, transferring the inked image.

Advantages of Ink Cup Pad Printing

Ink cup pad printing offers numerous advantages over other printing methods, including:

- Versatility: Suitable for printing on a wide range of substrates, including irregular and curved surfaces.

- Precision and Detail: Enables precise printing of intricate designs and fine details.

- Durability: Prints are resistant to fading, scratching, and other forms of wear.

- Cost-Effectiveness: Offers a relatively low cost per print, especially for high-volume production runs.

- Environmentally Friendly: Uses less ink and generates minimal waste compared to other printing processes.

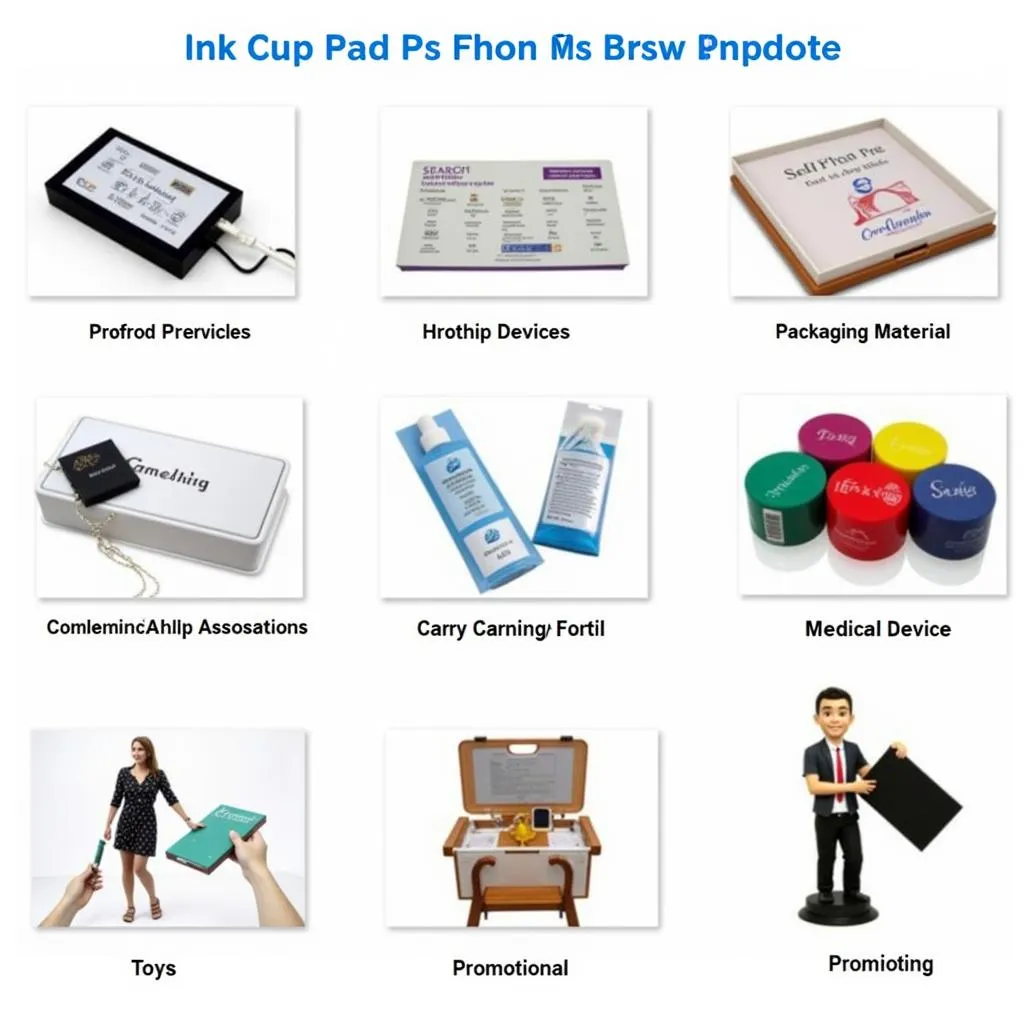

Applications of Ink Cup Pad Printing

Ink cup pad printing is used in a diverse range of industries, including:

- Electronics: Printing logos, serial numbers, and other markings on electronic devices.

- Packaging: Printing product information, branding, and graphics on packaging materials.

- Cosmetics: Printing logos and designs on lipstick tubes, compacts, and other beauty products.

- Medical Devices: Printing markings, logos, and barcodes on medical instruments and equipment.

- Toys: Printing graphics and designs on toys and games.

- Promotional Products: Printing logos and designs on pens, keychains, and other promotional items.

Considerations for Ink Cup Pad Printing

When considering ink cup pad printing, there are several factors to consider:

- Substrate Compatibility: Not all materials are suitable for pad printing. Some materials require specific inks or pre-treatment for successful printing.

- Design Complexity: The complexity of the design can influence the printing process and costs.

- Production Volume: High-volume production runs can benefit from the cost-effectiveness of pad printing.

- Ink Selection: Different inks offer varying properties, such as durability, color, and adhesion.

- Quality Control: Maintaining consistent print quality requires careful calibration and monitoring of the printing process.

Ink Cup Pad Printing: Your Best Printing Solution

“Ink cup pad printing is a versatile and reliable printing technique that offers exceptional precision and durability. Its adaptability to various substrates and its cost-effectiveness make it an ideal solution for a wide range of applications,” said Dr. Amelia Thompson, a renowned expert in printing technologies.

Frequently Asked Questions

Q: What types of inks are used in ink cup pad printing?

A: Ink cup pad printing uses specialized inks designed for the specific substrate and application. They can be solvent-based, water-based, UV-curable, or epoxy-based, each offering unique properties and benefits.

Q: Can ink cup pad printing be used for printing on curved surfaces?

A: Yes, ink cup pad printing is specifically suited for printing on curved and irregular surfaces. The flexible pad conforms to the shape of the substrate, ensuring even ink transfer.

Q: Is ink cup pad printing suitable for high-volume production?

A: Ink cup pad printing is highly efficient and well-suited for high-volume production runs. It offers cost-effectiveness and consistent print quality for mass production.

Ink Cup Pad Printing: A Solution for Your Needs

If you are seeking a printing solution that offers versatility, precision, and cost-effectiveness, ink cup pad printing is an excellent option. Consider the advantages and applications outlined in this article and contact us today to discuss your specific printing requirements.

Illustration of Ink Cup Pad Printing Process

Illustration of Ink Cup Pad Printing Process

Various Applications of Ink Cup Pad Printing

Various Applications of Ink Cup Pad Printing

Ink Cup Pad Printing Quality Control

Ink Cup Pad Printing Quality Control

If you need any assistance or have further questions about ink cup pad printing, reach out to us. Our team of experts is available 24/7 to provide you with tailored solutions and support. Contact us at:

- Phone: 0372999996

- Email: [email protected]

- Address: 236 Cầu Giấy, Hà Nội.